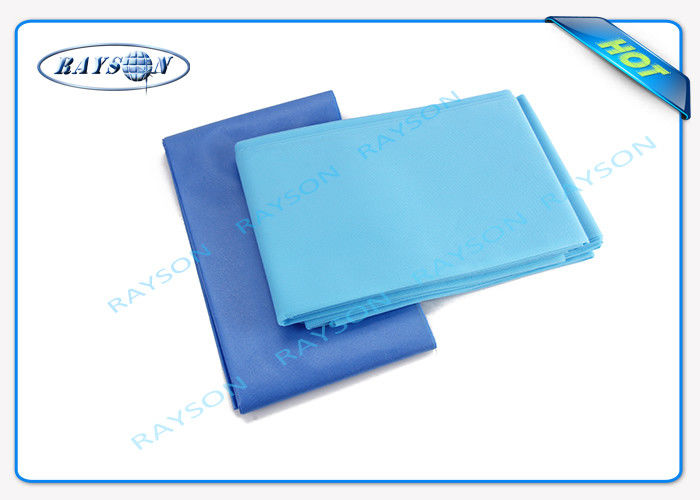

Hydrohobic Spun Bonded Non Woven Disposable Bed Sheet With Pe Film For Patient

Product Details:

| Place of Origin: | China |

| Brand Name: | Rayson |

| Certification: | , ISO, OEKO TEX |

| Model Number: | RS-Bed Sheet |

Payment & Shipping Terms:

| Minimum Order Quantity: | 2000kg |

|---|---|

| Price: | NEGOTIABLE |

| Packaging Details: | Poly bags or carton box |

| Delivery Time: | 20-30 days after deposit |

| Payment Terms: | T/T, L/C, D/A, D/P |

| Supply Ability: | 2000 Tons/month |

|

Detail Information |

|||

| Material: | Spunbond Non Woven | Thickness: | 20gsm To 150gsm |

|---|---|---|---|

| Technic: | Spunbonded Or SS | Feature: | Disposable, Anti-bacteria, Non Toxic |

| Logo Printing: | Acceptable | ||

| Highlight: | disposable bed sheets for hospital,non woven bed sheet,spun bonded disposable sheets for patients |

||

Product Description

Hydrohobic spun bonded non woven draw sheet with PE film for patient

Quick Detail:

|

Material |

100% Virgin Polypropylene |

|

Nonwoven Technics |

Spun-Bonded |

|

Pattern |

Embossed/Seasame |

|

Width |

5-320cm/ 2”--126” (can split into different size) |

|

Weight |

10-150gsm |

|

Color |

Full Color Range |

|

Label Supply |

Customer label/Neutral label |

|

Package |

Roll packed with 2” or 3” paper core inside and polybag outside |

|

Cutting piece size |

80x210cm, 100x210cm, 150x220cm, or customized |

|

Package |

Individual packed or bulk packed(15 to 25pcs in a polybag) |

|

Lead time |

25 days after 30% deposit |

|

Certification |

& INTERTEK |

Characteristics:

- Made from 100% virgin polypropylene

- Good strength and elogation

- Soft feeling,nontextile,eco-friendly and recyclable

- Anti-bacterial, hydrophilic

Flow Charts

- 1st step of production: Raw materials production as per order’s request,whole-process quality supervision including fabric tension thickness tolerance,color difference .etc.

- 2nd step of production: Fabric cutting & accessories preparation.

- 3rd step of production: Sewing for cutting-pieces,sewing machine’s debugging,whole-process quality supervision including thread tension and stitch density,product size tolerance .etc.

- 4th step of production: Packing for products.

- 5th step of production: Quality inspection for products.

- 6th step of production: Delivery to warehouse.

- 7th step of production: Container-loading for shipment.

![]()